by Jonathan Bultemeyer, SPI Ambassador

Sustainability is a term that has become increasingly prevalent in recent years. While the intentions behind it are commendable, the challenge lies in making such a broad goal measurable. This article explores sustainability in the context of print, specifically focusing on its role in industrial parts and their longevity.

Understanding the Lifecycle in Sustainability

One of the most crucial aspects of sustainability is the timeframe over which the footprint is measured. The broader the scope of a product’s lifecycle, the more realistic the sustainability assessment—though this also makes the calculation more complex. The concept of cradle-to-cradle is widely used to represent a product's entire lifecycle, including some pre- and post-production processes. However, cradle-to-cradle typically considers only the product itself, not necessarily the lifecycles of its individual components.

Today, discussions around sustainability have evolved to encompass a circular economy. This concept extends beyond individual product lifecycles and instead considers a holistic economic framework, which varies from industry to industry.

When evaluating the impact of print, it is essential to extend the product lifecycle to include the pre-processes involved. This approach ensures a more comprehensive sustainability calculation.

The Role of Print in Industrial Production

Print applications vary significantly, from traditional graphics to industrial parts. This article will focus solely on industrial part production. Despite efforts to establish a universal definition of “industrial” printing, no single definition has been agreed upon. For this discussion, we use the ESMA definition: industrial parts are those where print is functional or enhances the product but is not essential for its operation.

Examples of functional printing include cover glass for cell phones and printed electronics. Meanwhile, an example of enhancement printing would be a glass bottle with printed branding—the bottle functions without print, but the print adds value. In contrast, graphics printing involves products where print is integral, such as posters, which hold no inherent value without the printed content.

Evaluating Print Technology for Sustainability

When considering sustainability in printing, the most sustainable print technology is the one that extends a product’s lifespan the longest. If we analyze only the print process itself, sustainability values can be assigned to materials and processes used. While this approach works well for graphics printing—where print represents a significant portion of the product’s value—it is insufficient for industrial part production, where print constitutes a negligible share of total production costs (<5% in some cases, such as FIM parts).

For industrial parts, the most significant sustainability factor is product longevity. A short-lived product amplifies production costs and sustainability impacts, whereas a long-lived product distributes these costs over an extended period. Thus, the print process that contributes to the longest product lifespan has the least negative impact on sustainability.

This principle is reflected in the European Union’s Green Deal, which includes multiple forward-looking regulations aimed at extending product life cycles. These include:

- Extended Producer Responsibility (EPR)

- Extended Sustainable Producer Responsibility (ESPR)

- The New REACh Regulation

- Additional sustainability directives

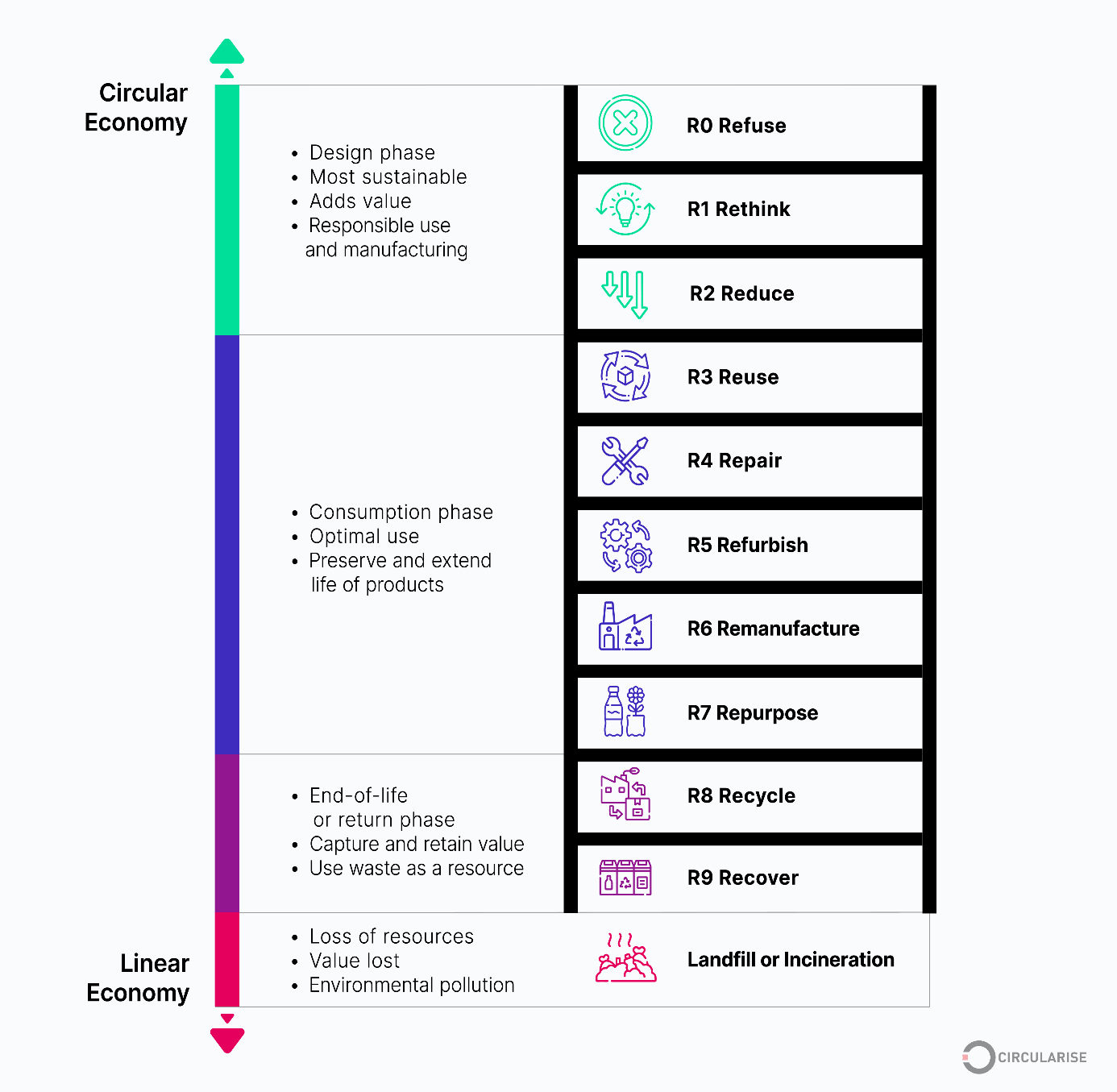

These directives align with the 9R Strategy, a comprehensive framework for promoting product longevity within the circular economy.

Screen Printing: The Most Sustainable Choice for Industrial Parts

It is unsurprising that the print technology enabling the longest product lifecycle is one with the highest percentage of resin in its ink formulation. Ink chemistries with only 3–5% resin content struggle to meet sustainability goals compared to those with 30–40% resin. Currently, very few ink chemistries allow such a high resin percentage.

The leading technologies in this regard are spray printing and screen printing. However, screen printing holds a distinct advantage: unlike spray printing, it does not require manual masking efforts and does not generate overspray waste. As a result, screen printing emerges as the most sustainable print process for industrial parts.

The logical conclusion is clear: screen printing’s ability to extend product life cycles makes it the most sustainable choice for industrial part production. This aligns with Europe's sustainability goals while serving as a caution against low-resin-content chemistries that are only suitable for short-term applications.

For a deeper dive into circular economy strategies, explore the 9R Strategies: 9R Strategies for a Circular Economy.

Conclusion

Sustainability in printing, particularly for industrial parts, must go beyond mere material assessments and consider longevity. The longer a product lasts, the less frequent its replacement, reducing the overall environmental impact. Screen printing, with its ability to support long-term product durability, stands out as the most sustainable option. As regulations continue to push for extended product lifecycles, adopting long-lasting print technologies will be key to achieving meaningful sustainability in industrial printing.

About the author:

About the author:

Between 2013 and 2015, Jonathan Bultemeyer has served as Chairman of the Board at ESMA (European Specialist Printing Manufacturers Association), leading initiatives to advance the screen printing industry. He was Managing Director of Corporate Central Functions at Marabu GmbH & Co. KG from January 2011 to August 2022. Before that, he spent over three years as Director of International Sales at Marabu, demonstrating his deep understanding of global market dynamics. Jonathan holds a degree in International Economics, providing a strong foundation for his leadership in the printing sector. Fluent in English and German, he excels in navigating international business environments, driving innovation, and fostering industry growth.